Besuchen Sie auch unsere neue Webseite, um die neuesten Ölskimmer-Modelle kennenzulernen: prt-gmbh.de

Visit our new website to find out about the latest oil skimmer models: prt-gmbh.de

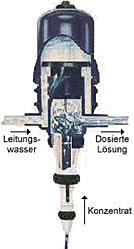

The electric current-less proportional dossing feeder from PRT GmbH is a precise fail-safe and simple device. Approved since 1979 in many different application ranges.

… in a remarkable simple electric current-less technology.

The accurate percentage of the water mixture will be positioned and as end mixture followed. Independently from water flow and variability from the pressure.

Industry generally, care of health, stock farming, market garden, cleanness general.

Essential and indispensable

For example for following, mixtures or fluids with percent exactly.

The electric current-less proportional dosing feeder from PRT GmbH is a simple, practical system, at the market since 1979 succsessful – ACCURATE, BOTTOM-OF-THE-LINE, TRUSTWORTHY.

The electric current-less proportional dosing feeder is functioning without electric power and will be connected to the water pipe easily: The water pressure is the driving power.

This unit is suctioning the concentrat out of the tank, is dosing the wished positioned percent and homogenized this in the mixing chamber together with the power water.

This now produced solution will be transported in the outlet water pipe.

After one-time regulation only at the dosing feeder, does not more has to be handled or controlled from outside.

The dosage of the discharged product is constant also at possible pressure or capacity deviations too and stiff proportional to the water capacity flowing through the dosing feeder.

HIGH DOSING ACCURACY, NO OVER DOSING – A REAL FEE TO THE ENVIRONMENT PROTECTION.

| Size | dosing rate % | Relation | Water l/h | Water Pressure bar |

| A 0,03/0,1 | 0,03 – 0,1 | 1:3333 – 1:1000 | 100 – 4.500 | 0,5 - 5 |

| A 0,3/0,125 | 0,03 - 0,125 | 1.3333 – 1:125 | 500 – 8.000 | 0,15 - 8 |

| A 0,07/0,2 | 0,07 - 0,2 | 1:1500 – 1:500 | 10 – 2.500 | 0,3 - 6 |

| A 0,1/0,9 | 0,1 – 0,9 | 1:1000 – 1:112 | 10 – 2.500 | 0,3 - 6 |

| A 0,2/1,5 | 0,2 – 1,5 | 1:500 – 1:67 | 100 – 4.500 | 0,5 - 5 |

| A 0,2/2 | 0,2 - 2 | 1:500 – 1:50 | 10 – 2.500 | 0,3 - 6 |

| A 0,2/2 | 0,2 - 2 | 1:500 – 1:50 | 500 – 8.000 | 0,15 - 8 |

| A 0,2/2 | 0,2 - 2 | 1:500 – 1:50 | 1.000 – 20.000 | 0,12 - 10 |

| A 0,5/3 | 0,5 – 3 | 1:200 – 1:33 | 100 – 4.500 | 0,5 - 5 |

| A 0,5 /4 | 0,5 – 4 | 1:200 – 1:25 | 10 – 2.500 | 0,3 - 6 |

| A 1/5 | 1 – 5 | 1:100 - 1:20 | 10 – 2.500 | 0,3 - 6 |

| A 1/5 | 1 - 5 | 1:100 – 1:20 | 500 – 8.000 | 0,15 - 8 |

| A 3/8 | 3 - 8 | 1:33 - 1:13 | 100 – 2.000 | 0,5 - 5 |

| A 3/10 | 3 – 10 | 1:33 - 1:10 | 10 – 2.000 | 0,3 – 4 |

| A 0,2/1,5 | 0,2 – 1,5 | 1:500 - 1:67 | 100 – 4.500 | 0,5 – 5 |

| A 0,5/3 | 0,5 – 3 | 1:200 - 1:33 | 100 – 4.500 | 0,5 – 5 |

| A 3/8 | 3 – 8 | 1:33 – 1:13 | 100 – 4.500 | 0,5 – 5 |

| A 0,2/2 | 0,2 - 2 | 1:500 - 1:50 | 500 – 8.000 | 0,15 - 8 |

| A 1/5 | 1 - 5 | 1:100 - 1:20 | 500 – 8.000 | 0,15 - 8 |

| A 0,2/2 | 0,2 - 2 | 1:500 - 1:50 | 1.000 – 20.000 | 0,12 - 10 |

| B 0,03/0,3 | 0,03 - 0,3 | 1:3333 - 1:330 | 10 – 3.000 | 0,3 – 6 |

| B 0,2/2 | 0,2 – 2 | 1:500 - 1:50 | 10 – 3.000 | 0,3 – 6 |

| B 0,5/5 | 0,5 - 5 | 1:200 – 1:20 | 10 – 3.000 | 0,3 – 6 |

| B 1/10 | 1 - 10 | 1:100 – 1:10 | 10 – 3.000 | 0,3 – 6 |

| B 5/25 | 5 - 25 | 1:20 – 1:4 | 10 – 2.000 | 0,5 – 4 |

at type A = the mixture goes through the water engine, for it better mixing of the end liquid at type B = mixture does not go through the water engine, mixing of the end liquid is neraly comparable with type A, piston rod has a shaft sealing ring, to avoid that water is onto the piston |

||||