Besuchen Sie auch unsere neue Webseite, um die neuesten Ölskimmer-Modelle kennenzulernen: prt-gmbh.de

Visit our new website to find out about the latest oil skimmer models: prt-gmbh.de

Construction

| Type: | simple unit construction, total made of stainless steel |

| wiper: | by hand adjustable, very immun, wear resistant |

| total drain: | open, simple drain, against extra cost oil outlet drain with R 1″ AG outside thread |

| standard speed: | so designed that an effective oil recovery will be reached, at lowest water rate |

| gear motor: | 0,003 kW, 50 Hz, 220 V, simple construction with insulated cable and clamping box |

| disc diameter: | 200, 250, 300, 365 Ø |

For not or only less unsteadiness and high levels. At fall of levels up to lower edge of the disc the delivery of oil will be go back up to zero.

Application

For continuous and discontinuous separating oil and liquid grease floating on surface in spots or connected layers, as a thick layer or film or small spots from cold or hot condensate neutral up to basic or acid in calm and strong moving water.

For ground-water rehabilitation (bymeans of deep well), basin of treating, coolant amulsion, industrial effluents, Oil collecting basins, habour basin, refineries, railway depots, industrials washing-separators, shipping, degreasing bathes in galvanic firms (and industrial for metal processing), manufacturers for eatable oils, washing plants (for tankers, cars, lorries, busses, trams, trains, panzer/armor …).

Oils, liquid grease, petrol, kerosene, solvents and similar.

Performance range

| oil recovery | Q | up to approx. 1.000 l/h |

| submersible depth | ET | up to 520 mm |

| speed | n | 0,5 – 20 min–1 (depending on Ø) |

| temperature | t | up to 100 °C |

| disc-Ø | 250 – 1.400 mm | |

| oil outlet nozzle | R | 1 – 3″ AG (or spezial nozzle) |

| rst water content | < > | <> 1 % |

Function

Oil sticks to both sides of the down moving belt part, transported to top over the driving roll and nearly wiped off dry on down moving belt side, squashing away oil on the inside the belt is impossible with

our rolls.

Steep drains avoid, in usually viscocity, an oil block or splash over. Oil is quickly drained. Exactly horizontal mounting is not required. Floating solid parts and wind do not influence the function.

Capacity

Dependet from oil layer thickness, viscosity, disc-Ø, submersible depth, water movement and speed. Rough appr. figure per each disc in standard speed: half disc width on top of water level in mm = l/h.

Construction

| type: | robust industrial design |

| wipers: | adjustable by hand, very resistant, solid in consumption |

| total drain: | total closed, oil outlet nozzle with outside thread |

| standard speed: | so proportioned that there is the most effective oil recovery, with lowest water share |

| gear motor: | 0,011 kW, in 3x 400 V, over that 230/400 V, 50 Hz, IP 54 |

| disc-Ø: | 365 up to 1400 Ø |

| disc number: | up to 10 |

| painting: | undercoat, 2-fold of blue hammer finish paint, impact-resistant, bigger sizes with black special resistant paint |

Special design

Total made of polypropylen PP, multiple discs, as a floating unit, according to ATEX, pressure air drive, hydraulic drive, oil outlet heightened and in one line with the disc (special at heavy fluently fluid).

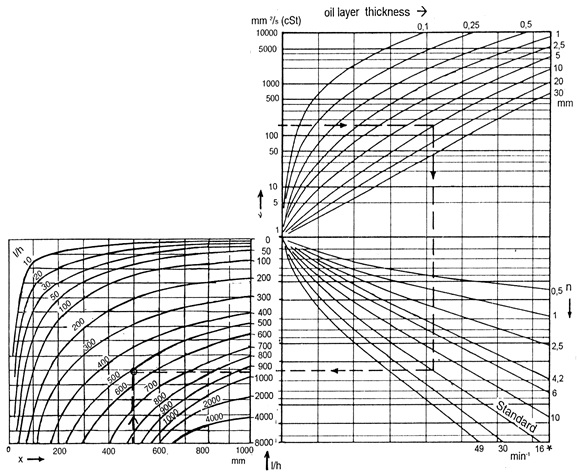

Performance curve

Example to read performance curve

How much oil in l/h at following operating condition:

viscosity = 160 mm2/s (cSt)

oil layer thickness = 10 mm

speed = 16 mm–1

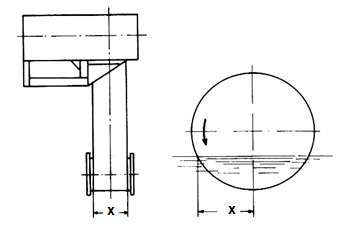

dimension for transporting width x = 500 mm

Result: without binding 500 l/h

* 16 min-1 only type OTF-2B size 400 and higher, further OTF-4B 50 up to 200/1 and OTF-5B 100 and 200 (the 16 min-1 curve in accordance about the capacity also for all other OTF-types in standard speed, which can be higher or slower), (not for types OTF-BE valid).

no-binding