Besuchen Sie auch unsere neue Webseite, um die neuesten Ölskimmer-Modelle kennenzulernen: prt-gmbh.de

Visit our new website to find out about the latest oil skimmer models: prt-gmbh.de

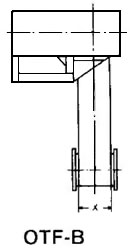

Swaying or more depth of water

Swaying or more depth of water

For ground-water rehabilitation (bymeans of deep well), basin of treating, coolant amulsion, industrial effluents, Oil collecting basins, habour basin, refineries, railway depots, industrials washing-separators, shipping, degreasing bathes in galvanic firms (and industrial for metal processing), manufacturers for eatable oils, washing plants (for tankers, cars, lorries, busses, trams, trains, panzer/armor …).

Oils, liquid grease, petrol, kerosene, solvents and similar.

| oil recovery | Q | up to 4.000 l/h |

| submersible depth | ET | up to 25 m |

| speed | n | 0,5 – 49 min–1 (optional Ø) |

| temperature | t | up to 130 °C |

| oil outlet nozzle | R | 1 – 8″ out side thread |

| rest water content | < > | <> 1 % |

A tension roll holds the belt vertical. Falling out is impossible even if the water has turbulences, wind or if there are solid parts between belt and tension roll.

A tension roll holds the belt vertical. Falling out is impossible even if the water has turbulences, wind or if there are solid parts between belt and tension roll.

Oil sticks to both sides of the down moving belt part, transported to top over the driving roll and nearly wiped off dry on down moving belt side, squashing away oil on the inside the belt is impossible with our rolls. Steep drains avoid, in usually viscocity, an oil block or splash over. Oil is quickly drained. Horizontal mounted.

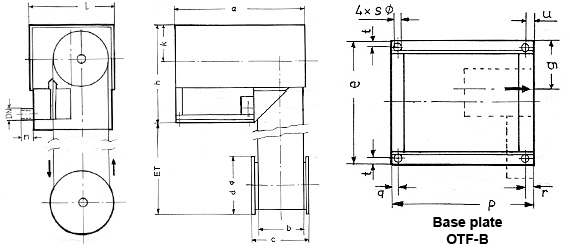

| Type: | OTF-1 B, 2 B (with plastic belt) | OTF-4 B (with stainless steel belt) |

| OTF-3 B (total of polypropylene) | ||

| Wipers: | by hand adjustable, very resistent, wear-resistent | |

| Drains: | very steep arranged, large-volumed | |

| Total drain: | otal closed with best sloping position (at size 60 open), oil outlet nozzle with R (Withworth, DIN 259), oil outlet right hand seen from motor, about extra price left hand too | |

| Changing the belt: | at mounted bonnet without any disassembly, at bigger units take bonnet away | |

| Driving roll: | variable in the width, with free space at the contact surface | |

| Tension roll: | with free space at the contact surface, special high border and high weigth, falling out of the belt is impossible | |

| Bonnet: | sheet steel galvanized, at bigger units black, special resistent special paint | |

| Standard speed: | so proportionated that there is the most effective oil recovery, at lowest water share | |

| Gear motor: | 0,011 – 0,12 kW, 230/400 V (Size 60 with 0,011 kW, 3x400 V), IP 54, 50 Hz | |

| Counter bearing: | from OTF-4 B 200/2 and from OTF-2 B 600 | |

| Submersible depth (ET): | inched proportion from 250 up to 25.000 mm | |

| Width of belt: | at plastic belt 30 – 2.000 mm, at stainless steel belt 50 – 1.000 mm (= 5 x 200 mm) | |

| Paint: | first coad, 2-fold hammer effect enamel blue, impact resistant, bigger sizes black but special resistent special paint | |

* Bigger DN (oil outlet nozzle) are deliverable, if oil has higher viscosity.

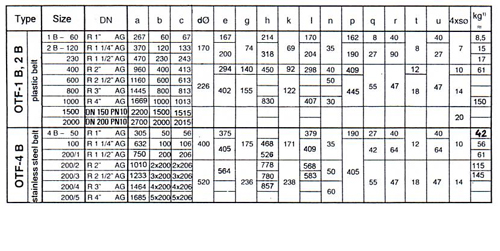

Example to reas perfomance curve:

Example to reas perfomance curve:

How much oil in l/h in following operating condition:

Viscosity = 160 mm 2/s (cSt)

Oil layer thickness = 10 mm

Speed = 16 min1

Transporting width dimension x = 500 mm

Redsult: approx. 500 l/h

* 16 min–1 only OTF-2B from size 400 and from size OTF-4B 10 (the 16-min–1 performance curve in accordance about the capacity also for all other OTF-Types in standard speed).

All datas are subjected to alteration!